Waterproof Smartphones

New sustainable, durable material solutions are required as smartphone and electronic device OEMs push for longer lasting, faster charging product features. Since 2015 Xtalic has led the industry by developing the earliest rapid material design and test capabilities. We continue to improve upon our existing solutions using XTALIC’s advanced material design platform based on computational models from the labs at MIT.

Downloads

Waterproof smartphone connectors are exposed to damaging corrosive environments.

XTALIC developed an immersion corrosion test using artificial perspiration, 5V and durability for rapid stack development.

Standard solutions failed to provide users with a reliable device.

XTALIC solutions provide up to 9x longer life.

Learn How To Transform Your Products

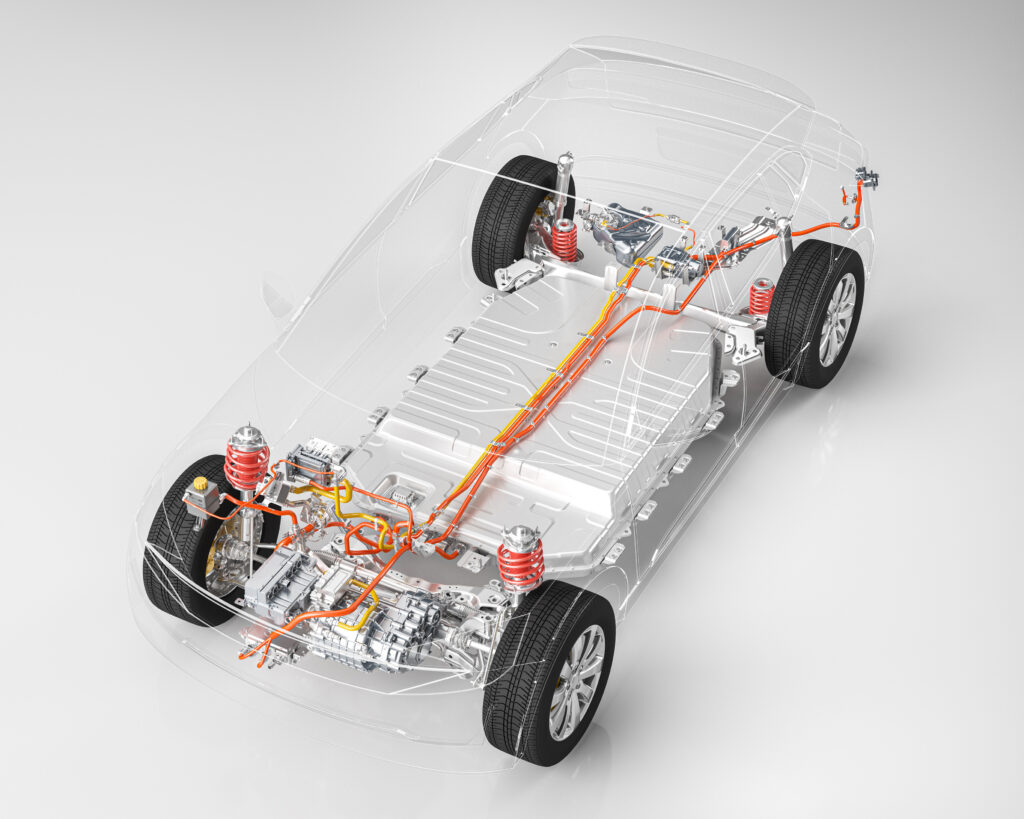

LUNA® is one of the strongest highest temperature silver alloys in the world. As the automotive industry moves fleets from ICE to EV platforms, the powertrain performance, safety, and reliability is provided through advanced electronic material technologies that enable a longer life and higher operating temperatures.

As electronics move from our smartphone to our bodies through wearable or medical devices, the materials used are required to be safer. LUNA® enables the removal of nickel from charging contacts.

XTRONIC® has saved datacenter OEMS more than $178 Million in gold and 78 Million Kg of CO2. By replacing precious metals in electronics, XTALIC is able to get you closer to meeting your ESG and sustainability goals. Today precious metal reduction is being explored across consumer devices using our advanced material design platform based on computational models from the labs at MIT.