Safe Wearables

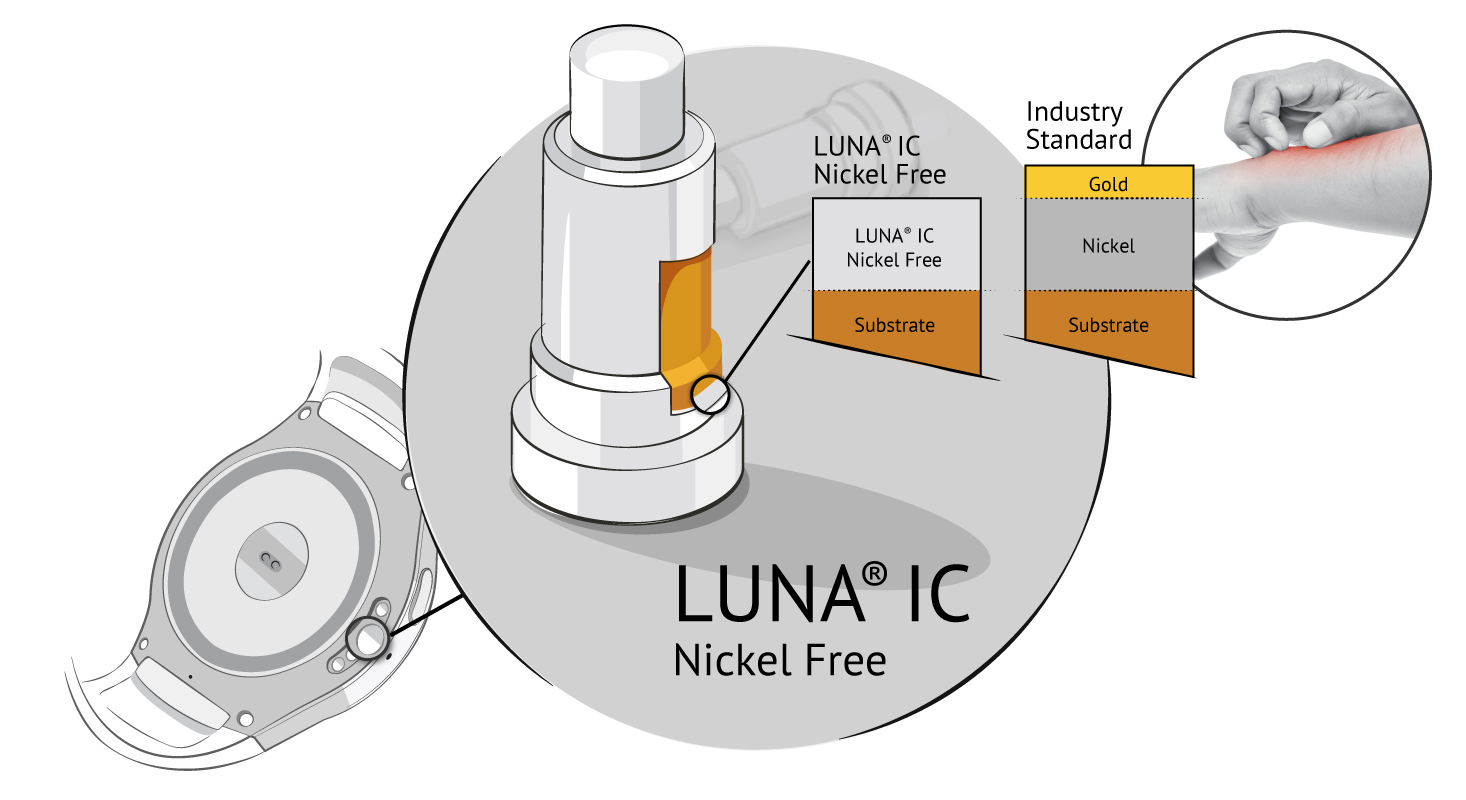

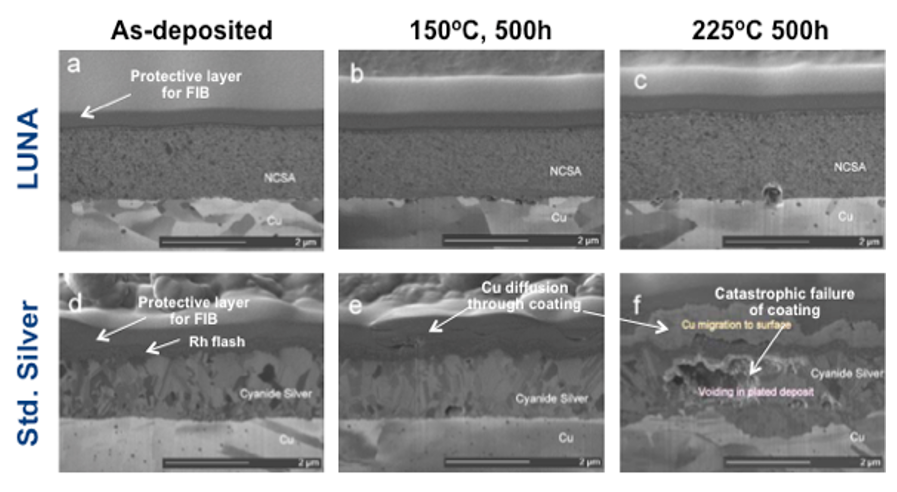

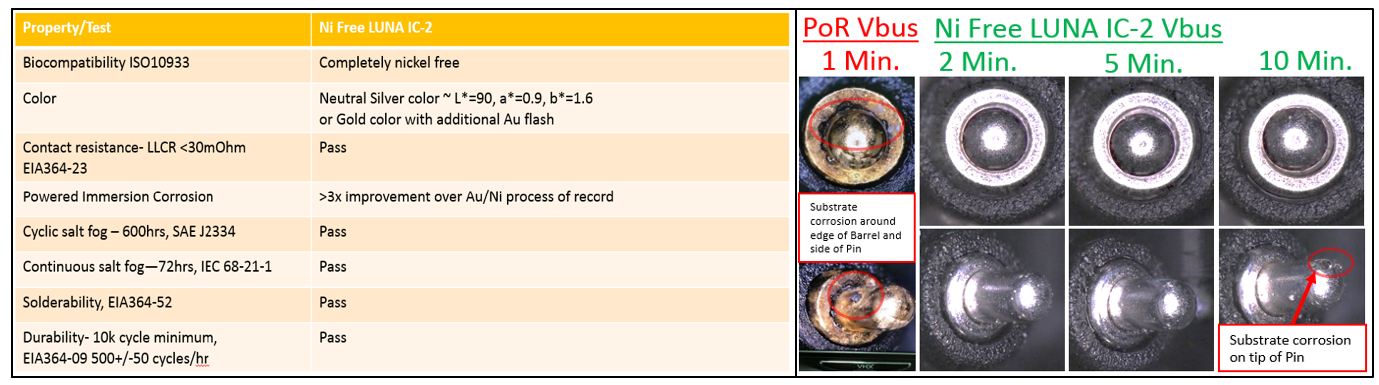

Nickel leaching onto skin causes more than 10% of the population contact dermatitis. XTALIC’s LUNA® nanostructured silver alloy provides the critical protective diffusion barrier layer needed to provide durable electronic connections without the use of nickel. As the demand for safe wearables continues to increase the base materials that house the components of such devices will undergo pressure by regulations. Therefore new advanced materials solutions must be developed to power the next generation of wearable electronics. XTALIC’s proven advanced material design platform based on computational models from the labs at MIT can provide the materials solutions for safer wearables by engineering stable grain sizes at the atomic level to supercharge their properties and replace poorly performing unsustainable materials.

Downloads

Learn How To Transform Your Products

LUNA® is one of the strongest, highest temperature silver alloys in the world. As the automotive industry moves fleets from ICE to EV platforms, the powertrain performance, safety, and reliability is provided through advanced electronic material technologies that enable a longer life and higher operating temperatures.

As smartphones shift to higher charging potentials and waterproofing claims, the USBC charging connector requires high performance advanced material technologies. XTRONIC® is a cornerstone for more than 2 billion smartphones that have fast charge waterproof features. These solutions are being explored across new applications as the world moves to electrify bikes, medical devices, and wearables.

XTRONIC® has saved datacenter OEMS more than $178 Million in gold and 78 Million Kg of CO2. By replacing precious metals in electronics, XTALIC is able to get you closer to meeting your ESG and sustainability goals. Today precious metal reduction is being explored across consumer devices using our advanced material design platform based on computational models from the labs at MIT.