Nanostructured metal alloys outperform traditional metals

MARLBOROUGH, MASSACHUSETTS, USA, June 30, 2016 — XTALIC introduced LUNA® USB earlier this year as a newly engineered connector plating technology that uses Xtalic nanostructured metal alloys to provide USB-C connectors with superior immersion corrosion protection. Today the Xtalic team is accelerating many key smartphone OEM qualification programs as well as the manufacturing footprint in Asia to support mass production. The mobile electronics industry has strong interest in LUNA USB, which is driven by the market push towards waterproof solutions and the more demanding requirements of the USB-C connector platform.

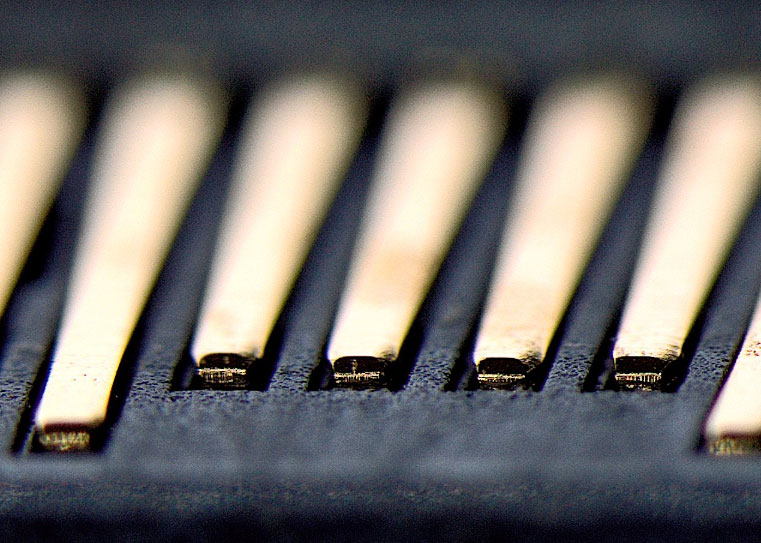

While electrical connectors are generally designed to survive and perform in a range of corrosive environments, the mobile electronics application is particularly challenging for two reasons. Firstly, mobile electronics connectors are routinely exposed to corrosive liquids, or an immersion corrosion environment, which can be very aggressive. Secondly, when charging devices are plugged in, there is current flowing through the connector and corrosion is dramatically accelerated. Exposure of the charging cable or the smartphone charging port to human perspiration, beverages, or other corrosive media will lead to rapid corrosion when the device is charging (or “under bias”). Gold is typically used as a connector finish in a range of demanding applications, but gold finishes are unable to meet the new mobile industry performance standards and rapidly disintegrate in these challenging immersion corrosion environments.

The problem becomes more acute as smartphones convert to the USB-C standard, which allows for higher voltage and faster charging. In an aggressive environment, traditional materials are unable protect against corrosion at these higher voltages.

LUNA® USB meets or exceeds the performance of hard gold when evaluated by accepted industry standards, including the EIA–364 connector standard. LUNA® USB delivers a significant performance improvement of up to 60X in immersion corrosion resistance under bias.

The LUNA® USB technology is built using LUNA® and XTRONIC® patented nanostructured metal alloys. Xtalic designed the LUNA® USB technology to be applied in existing manufacturing processes and equipment within the smartphone OEM supply chain, allowing for accelerated deployments in support of waterproofing strategies. Our technology is also being explored as a solution to remove nickel from wearables contacts and to decrease thickness in smartphone enclosures.

Publications: https://xtalic.wpengine.com/publications/

Contents

About Xtalic

Xtalic, founded in 2005, develops and commercializes the revolutionary ability to engineer metal alloys at the Nano-scale and creates tailored, stable alloys with valuable new properties. Our alloys have been broadly adopted in mobile and enterprise electronics applications, have been approved and deployed by more than twenty leading electronics firms, and are in use in more than 7 billion contacts worldwide. Xtalic operates globally and expects to double their manufacturing footprint in Asia during 2016. For more information please visit www.xtalic.com.

Media Contact

Robert Legg, Director of Product Management and Marketing

1-508-485-9730

Rlegg@xtalic.com