The Wall Street Journal, and businesses and industries worldwide, are buzzing about ESG, an acronym for Environmental, Social, and Corporate Governance. ESG encompasses the concept that improving our designs and reducing our environmental impact of gold mining on the planet can ultimately lead to improved financial success.

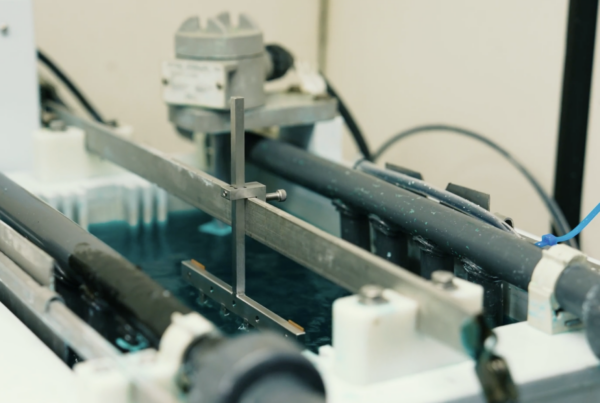

In electronics, gold is the standard choice in material, providing reliable performance, especially in electrical connectors. A typical smartphone has about 30 board-to-board connectors joining the cameras, batteries, speakers, and processors. This design allows for the easy assembly of smartphones with various components and supports needed repairs. While gold is expensive, the cost is partially mitigated by plating a very thin layer on the surface of connectors.

With hundreds of electrical contacts coated with the gold layer, it all adds up. Each smartphone averages about seven milligrams of gold in the connectors — about 38 cents worth of gold at today’s market price.

While seven milligrams doesn’t sound like much, couple that with massive manufacturing volumes (about a billion smartphones per year) and a product life of two to three years. That means seven metric tons of gold are used each year to make smartphones. (We previously wrote about saving a ton of gold (literally) in the electronics industry using Xtalic technology.)

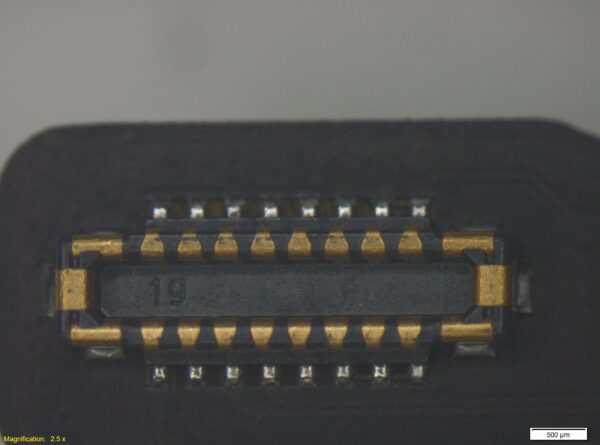

Figure 1. Example board-to-board connector with gold plating from a smartphone.

Contents

Environmental Impact of Gold Mining

Since only about 3% of the world’s smartphones are currently recycled, more and more gold must be mined from the earth each year to meet consumer demand. We can calculate the environmental toll of mining gold through a life cycle assessment (LCA). This process analyzes the environmental impact of mining the metals out of the ground, purifying and refining them, and transforming them into a product we can use. All this includes carbon dioxide emissions, energy to power equipment, chemical impacts from the processing, etc. To make these environmental impact factors something we can compare across industries, a common practice is to represent these factors in terms of equivalent kilograms (kg) of carbon dioxide (CO2) emitted. Carbon dioxide is a well-known greenhouse gas, and through the process of LCA, we have a useful way to visualize our impact on the planet.

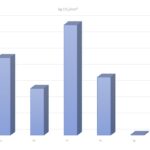

There are plenty of experts who can perform LCA on various materials and processes. While the analysis methods vary from study to study, a reasonable comparison of various precious metals LCA is shown in the chart in Figure 2 below, gathered from various scholarly articles*.

Figure 2. Life Cycle Assessment of the environmental impact of various precious metal mining: Au (gold), Pd (palladium), Pt (platinum), Rh (rhodium), Ag (silver).

Figure 2. Life Cycle Assessment of the environmental impact of various precious metal mining: Au (gold), Pd (palladium), Pt (platinum), Rh (rhodium), Ag (silver).

Each of these precious metals has a role to play in smartphones. For electrical connectors, gold is the primary precious metal of choice. Unfortunately, gold has one of the higher environmental impact scores at 479 kg CO2 per cubic millimeter. Figure 3 below helps to visualize this statement.

Figure 3. Visualizing one cubic millimeter – enough gold for connectors in three mobile phones**.

Figure 3. Visualizing one cubic millimeter – enough gold for connectors in three mobile phones**.

The tiny cube on the finger is one cubic millimeter. To make that tiny amount of gold, miners produce 497 kilograms of CO2. The impacts of the other precious metals are similar to gold — except for silver. Silver’s natural abundance in the earth’s crust and substantially more efficient mining practices reduce the environmental impact of extracting and refining its ore. As such, the environmental impact for silver is much lower at just 4 kg CO2 per cubic millimeter.

Silver is about 120 times lower in environmental impact when compared to gold for the same volume.

Visualizing a kilogram of carbon dioxide gas is easy if we employ a visualization aid. Imagine that we placed all of the CO2 required to mine the gold for just one smartphone into a container. That container would need to be the size of a tractor-trailer (177kg or 90m3). By contrast, the volume of CO2 produced by mining silver is much lower, about the size of a medium-moving box (1.5kg or 0.7m3).

Figure 4. The CO2 equivalent volume for mined gold for just one smartphone would fill this moving truck — while the equivalent volume for mined silver would fill just one medium-sized box.

Figure 4. The CO2 equivalent volume for mined gold for just one smartphone would fill this moving truck — while the equivalent volume for mined silver would fill just one medium-sized box.

The tractor-trailer is an excellent visual to imagine the environmental impact of a single smartphone. But if we are talking about the production of one billion smartphones per year, to illustrate the environmental impact of the mined gold, we would need to imagine filling one billion tractor-trailers with carbon dioxide. And that one billion is just from the gold used on the connectors of new phones, not counting the rest of the internal components.

Figure 5. One billion trailer trucks would be required to hold all the equivalent CO2 produced from mining the gold needed for one year’s worth of mobile phones. Bumper-to-bumper in traffic, the line would stretch 10 million miles long or enough to wrap around the earth 403 times.

Figure 5. One billion trailer trucks would be required to hold all the equivalent CO2 produced from mining the gold needed for one year’s worth of mobile phones. Bumper-to-bumper in traffic, the line would stretch 10 million miles long or enough to wrap around the earth 403 times.

An Alternate Solution Exists With LUNA® – Nanostructured Silver Alloy

Replacing gold with silver could dramatically reduce the environmental impact. However, on its own silver, performs poorly in electrical connector applications. It is too soft and wears poorly.

Xtalic has invented a silver alloy that replaces gold plating on connectors — computationally designed and engineered to be tough, durable, corrosion resistant, and excellent for electrical properties.

Reality Check: Can we really replace gold plating with silver on board-to-board connectors? The answer is, Yes! While the gold plating is very thin at about 0.1um, the silver plating would need to be somewhat thicker to achieve the equivalent performance — or at about 0.5um. The overall impact looks like this:

- The net environmental impact is reduced by 24 times compared to gold

- The performance of the connectors remains the same

- The cost for the connectors is the same

- Processing speed and manufacturing throughput is about the same

There are many ways to meet our ESG goals, reduce our carbon footprint, and lessen our environmental impact on the planet. Nanocrystalline silver alloy use in smartphone connectors is one way — and can be achieved without impacting product cost or performance. The change per phone is small, just milligrams, but (as we have seen) in an industry with massive volume, it all adds up to a big change for our environment.

Xtalic’s nanocrystalline LUNA® materials are computationally designed for outstanding performance and have been commercialized for connector applications. The technology can be extended for use in board-to-board type connections as well.

Contact us, and let’s explore further.

* Reference:

1. The Environmental Profile of Platinum Group Metals

2. Greenhouse gas and gold mines Nearly 1 ton of CO2 emitted per ounce of gold produced in 2019

3. Are silver miners turning a corner on carbon emissions?

** Photo credit: Image used with permission. “A Quadrillion, To Scale,” by David Dick-Agnew. Ignis Fatuus, October 27, 2010.