OEMs are becoming more aware of the need for sustainable safe touch electronic materials as our watches, glasses, and other fashion accessories or clothing items integrate smartphone technology to become smart wearables.

In this article, Dr. Bob Hilty explores some of the industry standards for key electronic materials on wearables, the technical performance that is needed to replace these materials, and how the Xtalic team took the challenge of creating one safe wearable solution for the end users, manufactures and overall environment.

There are plenty of new wearable devices creating a buzz. Exogen has a portable ultrasound machine that can assist in ultrafast bone healing. Embr Wave has technology for active cooling using a device to combat heat flash symptoms during perimenopause. Oura has a new smart ring technology that measures blood oxygen levels while asleep, taking the concept of discreet electronics to a new level of personal fashion and miniaturization.

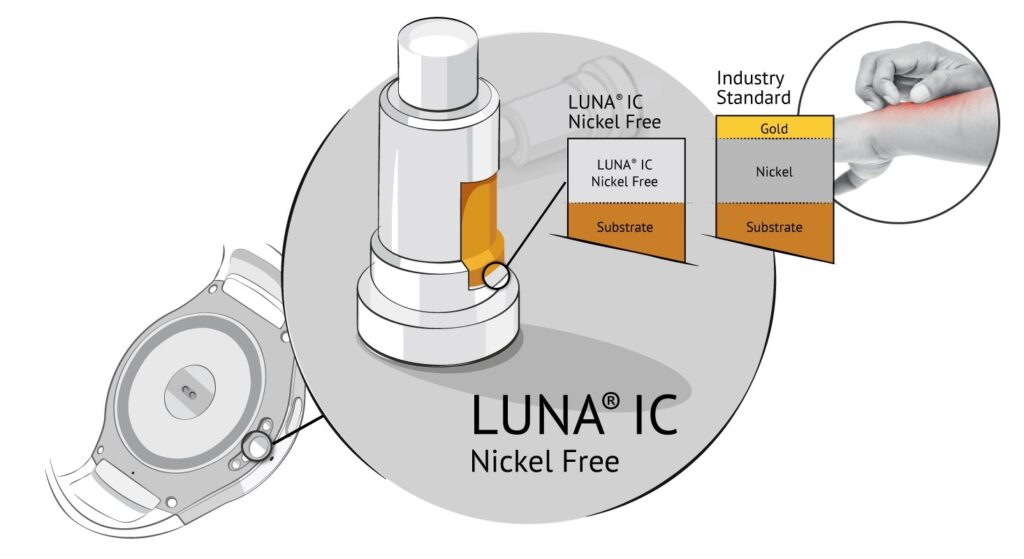

Nickel is a fabulous electronic material. It is strong, low cost, readily available, corrosion resistant, and easy to plate on printed circuit boards, wires, and electrical contacts. However, about 10% of the population is allergic to nickel and is prone to contact dermatitis. This becomes a key design challenge when we build wearable electronics designed to be in contact with human skin for many hours of the day and many days of the year. Some governments have even proposed to ban the use of nickel in these applications.

Platinum group metals are great alternatives for a few applications aside from the high costs. The crystal structure and atomic packing of palladium make it an ideal diffusion barrier, a way to prevent corrosion of other metals used in the system. This solution has been employed in durable decorative applications like high-end zipper pulls and consumer electronics connectors.

If the nickel is completely covered and 100% free of defects and porosity, then it can be used in conjunction with an alternate top layer, such as gold. This works for pogo pin style contacts on charging interfaces for wearable electronics but runs the risk of long-term nickel exposure when the contacts wear or get scratched in use. Designers are conflicted about making the gold as thin as possible for cost savings but thick enough to remain intact during use.

Our own LUNA® nanostructured silver alloy shows very good diffusion control performance as a barrier layer and is nickel-free. The LUNA silver-tungsten alloy has tungsten atoms segregated to the grain boundaries to make it a particularly effective diffusion barrier. Pure silver can work in applications where the diffusion performance is not as demanding, or the silver can be plated very thick. Silver alloys can also be an effective final finish for electrical contacts as silver alloys have low and stable contact resistance.

Our own LUNA® nanostructured silver alloy shows very good diffusion control performance as a barrier layer and is nickel-free. The LUNA silver-tungsten alloy has tungsten atoms segregated to the grain boundaries to make it a particularly effective diffusion barrier. Pure silver can work in applications where the diffusion performance is not as demanding, or the silver can be plated very thick. Silver alloys can also be an effective final finish for electrical contacts as silver alloys have low and stable contact resistance.

When designing LUNA, the team took the chance to create a safe non-cyanide base process in lieu of the standard cyanide silver process. While sourcing the tungsten, our team also focused on using recycled tungsten to ensure not only a safe product for the user and manufacturer but one that strives for a small environmental footprint as well.

Since the consumer will wear these devices, the industrial design elements of safe wearables are subject to trends in electronics, fashion, and jewelry design. As such, materials and finishes can have a big impact on the market acceptance of a new product, and product designers want as much flexibility as possible to expand their library of material choices. For non-electrical wearable material applications, paints and electrophoretic coatings provide good corrosion protection, a variety of colors, and low cost. E-coatings tend to be conformal and provide good all-over coverage and corrosion protection. New materials will need to interface with many of these traditional approaches to provide a path for clean legacy products and processes.

Xtalic continues to push for safer, cleaner electronic materials today. For safe wearable applications, the R&D team is gearing up to deploy a state-of-the-art nickel-free, high-performance rare earth magnet solution with XTALIUM®. XTALIUM is a suite of nanostructured aluminum alloys electroplated from ionic liquids. By using computational material design, we also enabled it to have the strength of steel and provide salt spray protection beyond 3000 hours leading to numerous potential applications.

Sign-Up for Behind the Scene Insights With Our Material Design Experts