Contents

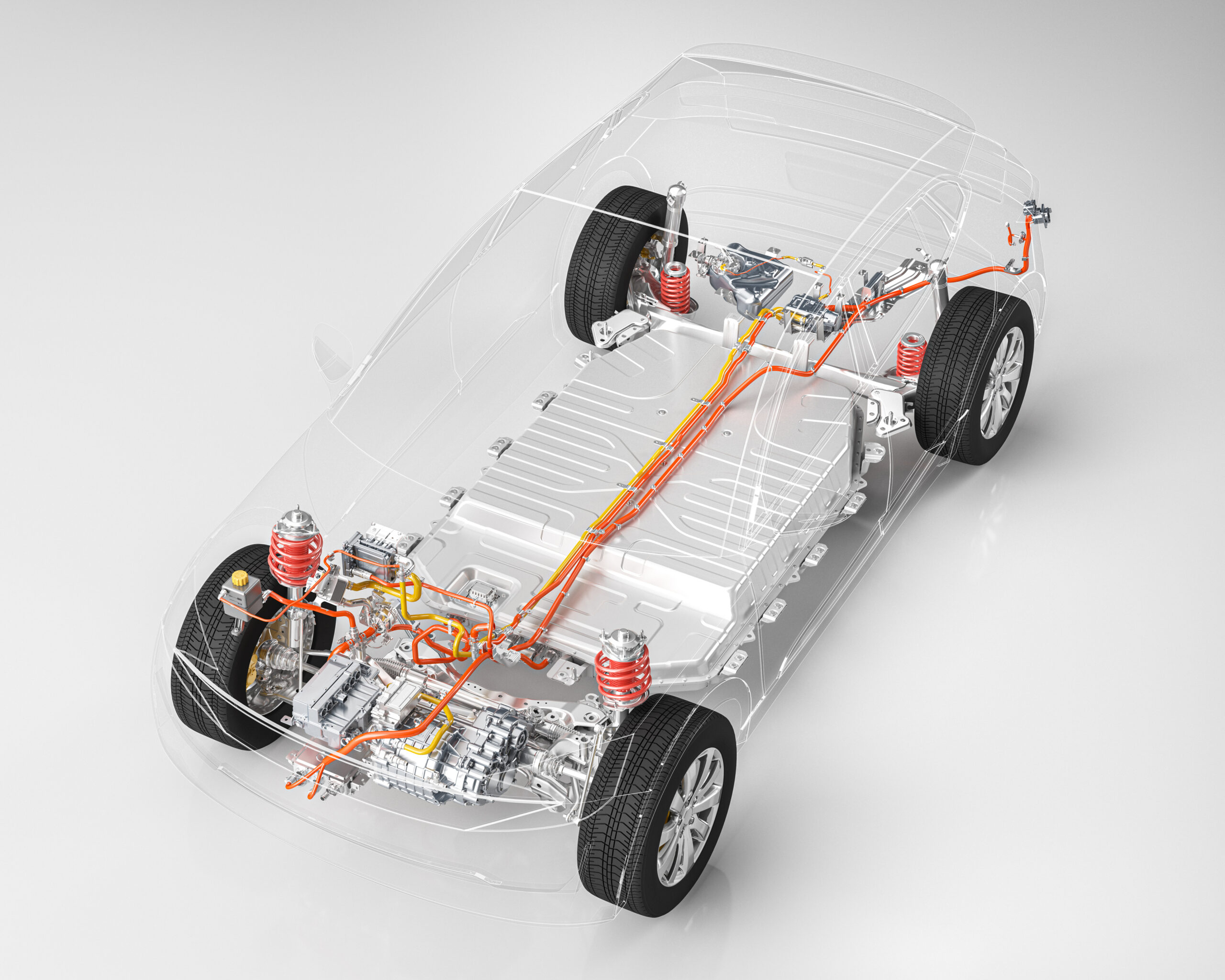

Design Challenges for Efficient and Reliable Higher-Performing Electric Vehicles

As electric vehicles continue to advance, powertrain engineers are confronted with the challenge of meeting demanding requirements, especially high-temperature coatings for EV interconnects.

The rapid evolution of EV technology demands innovative solutions capable of withstanding rigorous conditions while maintaining optimal performance. In response to this growing need, electric vehicle systems and design engineers are turning to advanced materials solutions that go beyond traditional methods of materials engineering available today.

With a proprietary computational material design platform, Xtalic can enhance the properties of metals by tailoring them for specific application needs. In this blog, we’ll delve into the use of LUNA®, a nanocrystalline silver alloy, as a high-temperature coating for EV contacts used in high-voltage cable harnesses.

Today’s Material Limitations in High-voltage Cable Harnesses

Acceleration, cost, safety, and reliability are a few of the primary considerations for consumers in the electric vehicle market today. Selecting appropriate materials for high-voltage cable harnesses is a critical concern for design engineers striving to optimize system performance across these key metrics. Traditional connector materials face significant challenges.

Traditional high-voltage cable harness materials encounter operating temperatures that cannot exceed a temperature limitation of 180°C. The silver plating on connectors could easily surpass this threshold if an excess of electrical current is applied. This creates a potential bottleneck for power delivery to motors or to the battery. This can occur under severe conditions such as heavy load pulling, hill climbing, rapid acceleration, regenerative braking, or prolonged use over the vehicle’s lifespan. At these high temperatures, the silver coating can soften at the contact interface leading to a rapid increase in resistivity and thermal runaway.

To address this challenge, engineers must explore alternative approaches:

- Employing more massive cables to extract heat from the contact surface, albeit at the expense of added weight and cost.

- Actively reducing or restricting the electrical flow through the system to reduce localized resistive heating, albeit at the cost of diminished acceleration/deceleration performance.

Stable High-temperature Coatings for EV Interconnects to Enhanced Performance, Reliability and Safety

To address the challenges that powertrain engineers face, Xtalic has engineered LUNA® – a thermodynamically stable nanostructured silver alloy that has proven to operate safely at temperatures up to 250°C in high-voltage electric vehicle cable harnesses. By utilizing an advanced material like LUNA, system engineers gain greater flexibility in designing the next generation of electric vehicles. Simply substituting LUNA for traditional silver in the connector contact surfaces empowers engineers to enhance system reliability and performance without compromising on safety or efficiency.

Learn more about our nanocrystalline silver alloy coatings for high-voltage EV interconnects – Click here for the white paper

Novel Nanocrystalline Silver Alloy Coatings to Boost Performance of EV High Voltage Interconnects and Charging Interfaces

Contact Us

"*" indicates required fields