We are in “conference season,” so it’s a great time to consider technology roadmaps and how advanced materials can make an impact. It’s also a great time to show off some of our new material design developments and products.

Let’s start with the International Microelectronics Assembly & Packaging Society (iMAPS) annual conference, where we had the chance to showcase our new Nanostructured nickel gold (Ni-Au) alloy.

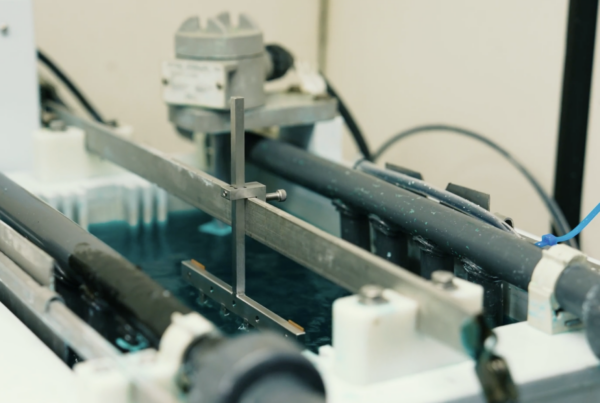

The Ni-Au alloy was developed with microelectronics packaging in mind, targeting electroformed spring elements that might be used for spring probe cards and other electrical interconnects.

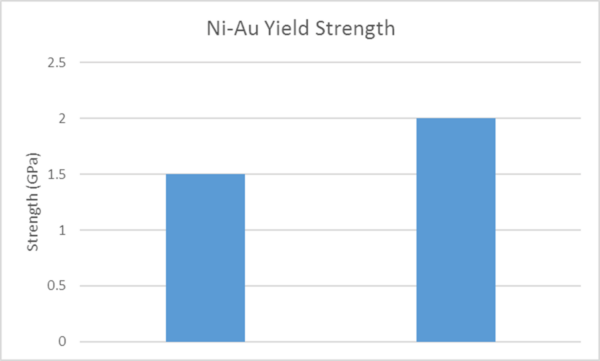

We leveraged our expertise in computational materials design, developed in the labs of MIT, to create a novel nickel alloy that uses a small amount of gold as an alloying agent to produce an incredibly strong and electrically conductive material. Gold is a strong nanocrystalline grain stabilizer in nickel, so we can use it quite efficiently to boost the properties into the target regime.

The presentation was standing-room only and had great engagement with the onsite audience.

You can download a copy of our peer-reviewed technical paper that we presented at the conference, “Novel Electroformed Ni-Au Alloy for High-Temperature Semiconductor Test Structures.”

Conferences also allow us to connect with new technologies and companies working in adjacent spaces.

Sivia Braun from Fraunhofer Institute for Electronic Nanosystems presented a novel approach to replace traditional copper pillars in multichip modules with electroformed aluminum pillars. This eliminates the dissimilar metal stacks in use today and could lead to improved reliability.

Ashraf Umar from SUNY Binghamton presented an analysis of the impact of bending on an RF antenna. These antennas are generally made by additive manufacturing approaches using materials like printed or aerosol-jetted silver inks. The mm-wave patch antenna arrays are built on flexible PET substrates. The modeling and experimental tests reveal the discrepancy between the modeled result and real-life samples, primarily due to the variability of the silver metallization. The silver material could have improved electrical conductivity (you lose some conductivity during the ink-fusing process), and as frequencies increase, we are seeing a need for a more smooth surface to reduce skin-effect-based perturbations at the surface, impacting overall return loss of the antenna. This means there may be an opportunity for new advanced materials development for 6G antennas and beyond.

The 2022 Materials Science and Technology (MS&T) conference was another great venue for sharing ideas about new developments in the advanced materials industry. This one was held in Pittsburgh, the home of steel and aluminum, which inspired a fundamental understanding of materials behavior within our industry.

The 2022 Materials Science and Technology (MS&T) conference was another great venue for sharing ideas about new developments in the advanced materials industry. This one was held in Pittsburgh, the home of steel and aluminum, which inspired a fundamental understanding of materials behavior within our industry.

After a few years of quiet R&D in the world of oil and gas, we are now seeing new contributions from this sector as they invest in improved drilling capability. Virendra Singh from Schlumberger presented a great paper on the use of diamond-like carbon (DLC) films on the surface of tools used in primary oil extraction. These hard and dense films are very wear-resistant and tolerant of the harsh environment of extraction. Boosting wear durability improves uptime for the tool and reduces waste. It’s a good example of an advanced material providing significant value in terms of performance and productivity.

Janelle Wharry of Purdue also gave a great presentation on the fundamentals of unexpected martensitic phase transitions in nickel chromium molybdenum (Ni-Cr-Mo) alloys. These are well-known superalloys for high-temperature applications which can also be used in irradiation environments. Dr. Wharry showed that the irradiation-induced defects can lead to martensitic transformations, in essence, nucleated by the displaced atom voids. This is a high-stacking fault energy alloy, so the phase transformation is not intuitively obvious. What was great about this talk was the engaging dialog with the audience after the talk, as the reasons for these behaviors we debated among various experts in the field.

While there are still more opportunities to connect with companies and scientists who study advanced materials yet this fall, these two conferences provide some insight into the inherent value we can create. These opportunities add great input to our technology roadmaps and influence us to update our plans for new materials and alloys, which can improve and enable the next generation of products.

Download a copy of our peer-reviewed technical paper presented at iMAPS 2022, “Novel Electroformed Ni-Au Alloy for High-Temperature Semiconductor Test Structures.”