As the inaugural newsletter it only seems fitting to explain the role Xtalic plays in computation material design. Metals are key building blocks that enable the performance of our future electrified products. The intention of this newsletter is to cover computational material design topics around new application needs, challenges that surround them, industry events, and the impact of macro trends.

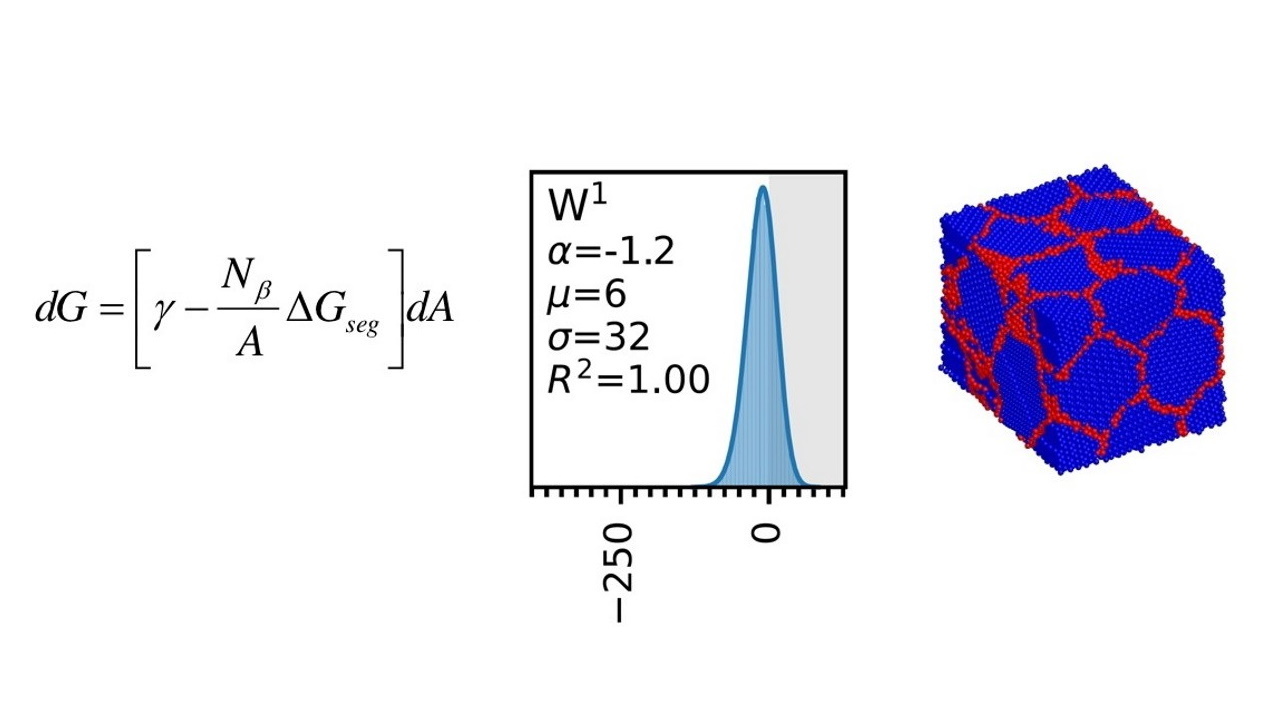

Xtalic has been pioneering the path of computational material design platforms since its founding from the labs of MIT in 2005. Today many of the largest electronic OEM supply chains in the world use Dynamic Nanostructure Control® of metal grain sizes through Xtalic’s electroplating chemistry and proprietary manufacturing software to provide desired product performance.

Designed in 2010, the XTRONIC® high performance alloy has already saved the top enterprise server build outs in the world from more than $100 million in gold and an environmental footprint required to mine and process more than one ton of gold. XTRONIC is the most proven electroplated hard nickel coating used in smartphone, router and switch connectors in the market. Today over 70% of your high-speed internet data connections and smartphones use Xtalic’s advanced electronic materials and alloys.

Advanced material design that enables reliable high-speed data and power throughput while balancing supply chain, cost and regulatory issues becomes more critical as macro electrification and miniaturization continue. Xtalic’s material design platform continues to evolve through collaboration with MIT and market leader feedback providing new solutions into the automotive and microelectronic industries.

Xtalic’s patented computational design technologies were once again leveraged to provide performance to enable automobiles shifting from ICE to EV. LUNA® is one of the world’s most durable hard silver coatings and operates at temperatures above 220 C. The LUNA contact surface finish provides EV owners with a safer more reliable high voltage powertrain cable harness and charging connector as opposed to the standard soft silver that is derated by the industry below 170 C on the contact surface.

Xtalic aims to further reduce the use of harmful, costly, and environmentally damaging materials while paving the way forward for the next generation of high-performance products. Solutions are being designed for emerging needs around rhodium, palladium, and gold alternatives as well as nickel free wearables, lead safe fashion accessories, and fine pitch semiconductor test. Xtalic’s XTRONIC, LUNA, novel low friction high wear platinum group alloys and high strength to modulus nanostructured nickel gold alloys, are poised to address these needs. By tailoring the properties of readily available safe materials to meet demanding performance needs we can provide alternatives for hard to replace materials and pave a more sustainable future.

Sign-Up for Behind the Scene Insights With Our Material Design Experts