In 1890 Nikola Tesla experimented with early wireless power transmission and the basic principles of those early studies are now employed in wireless charging technology for everyday devices like smartphones and watches. Technology has advanced dramatically since then, and today we are harvesting the power of advanced materials to boost the efficiency and charging speeds of wireless charged devices.

Moreover, there exists a demand for wireless charged devices that are environmentally sustainable and energy efficient. Consumers also require devices that are safe, energy controlled and power quickly regardless of precise alignment or positioning. When it comes to the future of wireless charging technology, the innovations in materials engineering will be crucial to the next generation of consumer electronics.

Contents

Advanced Materials as the Architects of Change

The physics of wireless charging technology dictates that the transmit and receive coils need to have some degree of alignment and proximity. This boosts efficiency and overall performance. The new Qi2 wireless charging standard includes the Apple Mag-Safe approach including magnets in the devices to provide effortless alignment to boost efficiency and charging speed.

Advanced materials offer an additional strategic advantage. Wireless charging coils will continue to rely on copper as the core conductor as it has the right blend of desirable properties: conductivity, cost, formability, and sustainability. Advanced materials can play a role in impacting the electromagnetic fields and the response of the coil to those fields.

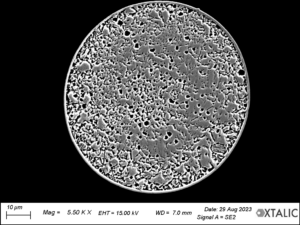

XenergyTM is the trademark of the nanostructured soft magnetic material Xtalic has invented for these applications. It is an iron-based alloy with nickel and cobalt that can be coated onto the surface of the coil conductor to boost the Q of the charging coil. The coating achieves this by affecting both the inherent inductive response as well as reducing the AC resistivity at high frequency.

These nanostructured metal materials are applied by electroplating and consume very little space with most coatings being 1um or less. By separating the functions of the core material (a conductor) with the coating (engineering the magnetic field response), we can effectively optimize these two characteristic properties independently to maximize the response.

Industry standard plating lines used for the production of fine wire are well-suited to apply this technology. Fast deposition speeds and manufacturing throughput allow for easy integration into the wires of the wireless charging coil. Using our prototype reel to reel plating line, we can coat fine gage wire like the 65um wire shown below.

Cross-section of a copper wire coated with Xenergy magnetic coating with the copper etched to reveal the structure.

As we embrace the benefits of wireless charging, we must also consider its environmental impact. The proliferation of electronic devices has led to increasing awareness of the environmental impact of the materials choices we make. Xtalic’s capabilities and technology aim to not only enhance the efficiency of wireless charging but also contribute to a greener future. By using Xtalic nanostructured metal alloys, manufacturers are not only reducing electronic waste but also minimizing the carbon footprint of the technology itself.

Paving the Path Forward for Advanced Materials and Wireless Charging Technology

The potential of advanced materials in wireless charging seems boundless. These materials are not only shaping the evolution of consumer electronics but are also opening doors to new applications. Industries like aerospace, medical devices, and manufacturing are set to benefit from the efficiencies and conveniences that wireless charging offers.

So, the next time you place your smartphone on a wireless charging pad, remember the advanced materials working tirelessly behind the scenes. They are the architects of change, the innovators of convenience, and the catalysts for a brighter, wireless future.